Day 1 :

Keynote Forum

Dr. Alexander L Yarin

University of Illinois, USA

Keynote: Biopolymer-derived nanofibers and their applications as biomedical materials and adsorbents for heavy metals removal from polluted water

Time : 9:30-10:30

Biography:

MSc-1977 (in Applied Physics), PhD (in Physics and Mathematics)-1980, DSc (Habilitation, (in Physics and Mathematics)-1989. Affiliations: The Institute for Problems in Mechanics of the Academy of Sciences of the USSR, Moscow (1977-1990); Professor at The Technion-Israel Institute of Technology (1990-2006; Eduard Pestel Chair Professor in Mechanical Engineering at The Technion in 1999-2006); Distinguished Professor at The University of Illinois at Chicago, USA (2006-present); Fellow of the American Physical Society. Prof. Yarin is the author of 4 books, 12 book chapters, 310 research papers, and 6 patents. Prof. Yarin was the Fellow of the Rashi Foundation, The Israel Academy of Sciences and Humanities, and was awarded Gutwirth Award, Hershel Rich Prize and Prize for Technological Development for Defense against Terror of the American-Technion Society. He is one of the three co-Editors of “Springer Handbook of Experimental Fluid Mechanics”, 2007, and the Associate Editor of the journal “Experiments in Fluids”.

Abstract:

Solution blowing of such plant-derived biomaterials as soy protein, zein, lignin, oats, sodium alginate and cellulose acetate, and such animal-derived biomaterials as silk protein (sericin), chitosan and bovine serum albumin, was demonstrated as a versatile, robust and industrially scalable approach to form monolithic and core-shell nanofibers from bio-waste. Mechanical properties of such nanofiber mats were investigated. The collected nanofiber mats were also bonded both chemically (using aldehydes and ionic cross-linkers) and physically (by means of wet and thermal treatment) to increase the tensile strength to widen the range of applications of such green nonwovens. Fluorescent dye Rhodamine B was used as a model hydrophilic drug in controlled release experiments after it had been encapsulated in solution-blown soy protein-containing hydrophilic nanofibers and the release kinetics associated with dye desorption was studied in detail. Also, the antibacterial activity of solution-blown soy protein nanofiber mats decorated with silver nanoparticles was studied. Nanofiber membranes containing such biopolymers as lignin, oats, soy protein, sodium alginate and chitosan were used for heavy metals adsorption from aqueous solutions in equilibrium in the batch experiments, as well as under the throughflow conditions. The results revealed attractive capabilities of these inexpensive nano-textured biopolymer adsorbents formed from waste materials using the process scalable to the industrial level. The results also elucidated the physico-chemical mechanisms of heavy metal adsorption on biopolymers.

Keynote Forum

Dr. Vakhtang Barbakadze

Professor Tbilisi State Medical University Georgia

Keynote: Biopolymer of Medicinal Plants with Anticancer Efficacy

Time : TBA

Biography:

1978 and 1999 has completed his Ph.D and D.Sci. at the ages of 33 and 54 years from Zelinsky Instiute of Organic Chemistry, Moscow, Russia and Durmishidze Institute of Biochemistry and Biotechnology, Tbilisi, Georgia, respectively. 2006 up to date he is the head of laboratory of plant biopolymers at the Tbilisi State Medical University Institute of Pharmacochemistry. 1996 and 2002 he has been a visiting scientist at Utrecht University (faculty of pharmacy), The Netherlands, by University Scholarship and The Netherlands organization for scientific research (NWO) Scholarship Scientific Program, respectively. He has published more than 80 papers in reputed journals.

Abstract:

dihydroxyphenyl and carboxyl groups are regular substituents at two carbon atoms in the chain. The repeating unit of this regular polymer is 3-(3,4-dihydroxyphenyl)glyceric acid residue. This compound is a first representative of a new class of natural polyethers. Then the racemic monomer 2,3-dihydroxy-3-(3,4-dihydroxyphenyl)propionic acid (DDPPA) and its virtually pure enantiomers (+)-(2R,3S)-2,3-dihydroxy-3-(3,4-dihydroxyphenyl)propionic acid and (-)-(2S,3R)-2,3-dihydroxy-3-(3,4-dihydroxyphenyl)propionic acid were synthesized for the first time via Sharpless asymmetric dihydroxylation of trans-caffeic acid derivatives using an osmium catalyst, a stoichiometric oxidant N-methylmorpholine-N-oxide and enantiocomplementary catalysts cinchona alkaloid derivatives (DHQ)2-PHAL and (DHQD)2-PHA as chiral auxiliaries. PDPGA has wide spectrum of biological activity: anticomplementary, antioxidant, antiinflammatory properties, burn and wound healing effect. PDPGA and DDPPA exerted anti-cancer efficacy in vitro and in vivo against androgen-dependent and androgen -independent human prostate cancer (PCA) cells via targeting androgen receptor, cell cycle arrest and apoptosis without any toxicity, together with a strong decrease in prostate specific antigen level in plasma. However, our results showed that anticancer efficacy of PDPGA is more effective compared to its synthetic monomer. Overall, this study identifies PDPGA as a potent agent against PCA without any toxicity, and supports its clinical application

Keynote Forum

Vimal Katiyar

Department of Chemical Engineering, Indian Institute of Technology Guwahati Assam -781039 India,

Keynote: Effect of Functionalized biopolymers on Stereocomplexation and Properties of Poly (Lactic Acid) Nanocomposite Films, Trays and 3D Printed Implants

Time : 10:50-11:50

Biography:

Prof. Vimal Katiyar is a Coordinator of Centre of Excellence for Sustainable Polymers, in the department of Chemical Engineering at IIT Guwahati, India. The centre of excellence on sustainable polymers is focusing on development of cost-effective, bio-based and biodegradable plastic products and related technologies using various feedstock including biopolymers such as cellulose, chitosan, proteins, various protein grafted polysaccharides. He has published more than seventy peer reviewed publications in highly reputed journals such as American Chemical Society and Nature publishing journals. He has supervised seven PhD students and more than twenty students are pursuing PhD under his supervision. His recently featured book entitled as ‘Bio-based Plastics for Food Packaging Applications’ is published by Smithers Rapra, UK. He is a co-inventor of numerous granted patents in various countries including India, USA, Canada, Europe, Japan, etc. His research group has received multiple national and international innovation awards in the development of bio-based polymeric products, nanobiomaterials, and related technologies.

Abstract:

This presentation highlights the use of available bio-resources for value added sustainable polymeric products for Engineering, Commodity and Biomadical Applications. Biopolymers can be extracted from renewable feedstock such as plants, marine animals, insects, etc. It is noteworthy to mention that so far biopolymers extracted from these sources have limited applications in large scale plastic production. Among the available bio-based synthetic plastics, polylactic acid (PLA) has made its own place due to its biodegradability and potential to replace conventional fossil based plastics. It is noteworthy to mention that properties such as melting point, heat deflection temperature and gas barrier properties limits its use in high temperature commodity and engineering applications. However, these limitations can be overcome by developing new class of high molecular weight stereocomplex PLA (sc-PLA). In this context, we have synthesized sc-PLA and its sc-PLA-bionanocomposites by using different biobased nanofillers which includes cellulose nanocrystals, silk nanocrystals, modified chitosan, etc. The GPC analysis reveals that the synthesized stereo-complex based bionanocomposites have molecular weight higher than 100 kDa. The formation of stereocomplex crystallites is confirmed by the XRD analysis. Melting point of the composite is increased even higher than 225°C which suggests the formation of stereocomplex crystallites and the crystallization temperature is enhanced upto ~155°C at nanofillers loading of 5 wt%. Due to the presence of various bionanofillers, ultimate tensile strength is enhanced significantly. Based on the studies, it can be concluded that bionanofillers are good candidates for enhancing the stereocomplexation in the PLA. In this talk, fabrication strategies for synthesis of stereocomplex-PLA-bionanocomposites and evaluation of their properties along with possible applications will be discussed. This talk will also include the processing of these bionanocomposites into caste films and injection molded products for biomadical applications.

- Advanced Biopolymers

Location: "Hyatt Regency Osaka, Osaka, Japan 1-13-11 Nanko-Kita Suminoe-Ku 559-0034 Osaka Japan"

Session Introduction

Jin Huang

Southwest University, China

Title: Focus on surface modification of cellulose nanocrystals to enhance mechanical properties of bio-based polyesters

Biography:

Professor Dr. Jin Huang is affiliated with School of Chemistry and Chemical Engineering, Southwest University, China. He received the PhD from Wuhan University, and completed postdoctoral research in Institute of Chemistry, Chinese Academy of Sciences. Thereafter, he has worked in Wuhan University of Technology from 2005 to 2015, and carried out some research in Grenoble Institute of Technology in this period. The one of his research interests focuses on “Developing chemical and physical methodology and technologies to manufacturing green materials from biomass resources”, and he has worked on the preparation and evaluation of bioplastics, composites and nanocomposites using natural polymers including cellulose, chitin and chitosan, starch, plant proteins etc., and explored some advanced applications. Especially, the surface chemical modification and new nanocomposites of cellulose nanocrystals are the main topics. Up to now, he has authored and co-authored more than 140 peer-reviewed journal publications, 1 monograph and 7 book chapters, over 40 granted patents, and many conference papers/presentations

Abstract:

Due to increasing concern about the environmental protection and the substitute of fossil resources, the development and applications of sustainable materials derived from biomass resources have aroused great interest. Especially, the bio-based polyester including poly(lactic acid) (PLA), poly(butylene succinate) (PBS), poly(3-hydroxybutyrate-co-4-hydroxybutyrate) (P(3,4)HB) etc., have been extensively attempted to develop environment-friendly materials and products. Furthermore, it is highlighted that the unique properties of nano-filler contribute to the enhancement of mechanical performances for polymeric materials. In comparison with inorganic nano-fillers, cellulose nanocrystal exhibits many advantages including renewability, biodegradability, biocompatibility, high specific modulus and so on, and shows a rod-like morphology and highly crystalline. As well known, the interface between nano-fillers and polymer matrix is the key issue to determine stress transferring among components, organization of polymer matrix and distribution of nano-fillers. Moreover, the strategies of small molecule-conjugation and polymer-grafting towards cellulose nanocrystals have been applied to regulate surface physicochemical properties, and hence to improve interfacial interaction and even formed chemical linkage between nano-filler and matrix, which gave high mechanical performances for the nanocomposites of cellulose nanocrystal-filled bio-based polyesters. For the bio-based polyester matrix, surface acetylation of cellulose nanocrystals was conducive to promoting their interfacial compatibility with hydrophobic polyester matrix together with an enhancement in mechanical properties of the as-prepared nanocomposites. With an increase of surface acetylation degree, the discrepancy in the surface energy between cellulose nanocrystal surface and polyester matrix gradually decreased, resulting in better affinity and stronger interaction between two components. Hence, homogeneous distribution of acetylated cellulose nanocrystals in polyester matrix was improved, which contributed to optimized reinforcement cellulose nanocrystal with less loss of elongation of the nanocomposites.

Ryan W. Davis

As a Principal Member, Sandia National Laboratories

Title: Cultivation and utilization of cyanobacterial exopolysaccharide for production of biobased polymers

Time : 11:50-12:35

Biography:

As a Principal Member of Technical Staff at Sandia National Laboratories, Ryan’s research has focused on science and technology for production of biobased commodities from renewable feedstocks using nonarable land and non-freshwater resources. Ryan recieved his Ph.D. in Physical Chemistry from the University of New Mexico and completed post-doctoral studies at Sandia Laboratories in New Mexico and California. Ryan has published >25 articles in peer-reviewed journals and is director of the Sandia Algae Raceway Testbed Facility

Abstract:

Development of polycultures has been identified as a potential means for overcoming several challenges facing scale-up of algae-based commodities which can displace petroleum but do not compete with food production. In this presentation, we describe findings from our recent studies on cultivation of a marine cyanobacterial consortium in open algae raceways, and downstream conversion to bioplastic. In the consortium, three distinct cyanobacterial cultivars were combined to provide nitrogen fixation, photoprotection, and high rates of secretion of extracellular polysaccharides in support of a long-term bioproduct ‘milking’ strategy. Following lab-scale investigations of various combinations of the individial cultivars to identify optimal algae raceway inoculation and maintenance strategies, the best performing consortia were successfully cultivated in pilot-scale algae raceways for >120 days. The growth trials indicated bioproduct concentrations >2 g/L consisting primarily of a variety of C5 and C6 monosugars which were recovered using a low-cost semi-continuous harvesting strategy. In addition to the remarkable stability of the consortium in open cultivation, measurements of culture density time course indicated insignificantly different log-phase specific growth rates at different levels of nitrate or carbon dioxide addition, which should have significant techno-economic and sustainability impacts for commercialization. Following recovery of the biomass and exopolymer, generation of cyanobacterial-derived bioplastic was demonstrated and performance characteristics were found to be similar to common biobased plastics, such as PLA. Initial technoeconomic analysis based on the product yield and corresponding biomass production, harvesting, and conversion costs indicate an Nth-plant model finished product cost of $600/ton.

- Biopolymers: Biomedical and Environmental Applications

Location: "Hyatt Regency Osaka, Osaka, Japan 1-13-11 Nanko-Kita Suminoe-Ku 559-0034 Osaka Japan"

Session Introduction

Seol-Ha

Seoul National University, Korea

Title: Biomimetic Coating of Hydroxyapatite on Glycerol Phosphate-Conjugated Polyurethane via Mineralization

Biography:

Seol-Ha Jeong fabricated hyaluronic acid based nanocomposite hydrogels for various biomedical applications. She has applied in-situ precipitation process to hyaluronic acid hydrogel for hydroxyapatite precipitation within the gels. Her evaluation evaluation based on in vitro and in vivo models creates new pathways for improving healthcare, including wrinkle improvement and wound dressing applications. She is also interested in polyurethane based composite systems with high functionality

Abstract:

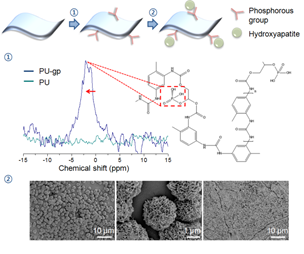

Statements of Problem: Polyurethane (PU) based biopolymers have been widely used in various medical fields due to a highly porous structure and controllable mechanical properties. However, it lacks of biocompatibility compared to natural polymers. In order to improve the biological properties, hydroxyapatite (HA) has been widely used for coating on PU. However, as PU has no specific sites for interactions with hydrophilic coating layers, coating stability had not been achieved without any further processes. In this study, glycerol phosphate (gp) was introduced as a new conjugate to improve HA coating stability on PU.

Orientation: PU-gp-HA was fabricated, following 2 step; (1) glycerol phosphate conjugation and (2) HA mineralization. PU-gp was fabricated through foaming reaction. During this process, gp was conjugated with TDI based PU prepolymer. Then, PU-gp was immersed in concentrated simulated body fluid (SBF) solution to induce HA mineralization on the surface of PU-gp.

Findings: gp was conjugated through urethane bonding with PU. Phosphate functional groups acted as nucleation sites for amorphous calcium phosphate in SBF solution to be anchored. Phosphate groups not only promoted HA nucleation, but also provided robust interface between PU and HA from exterior impacts. Most HA was detached from pure PU while large portion of HA remained on PU-gp after sonication. Filopodia of fibroblasts were well spread on PU-gp and PU-gp-HA than pure PU due to hydrophilic phosphate groups and bioactive HA. HA also activated fibroblasts’ proliferation remarkably from 3 to 5 day of culturing time.

Significance: This study demonstrated that elastomer modifying techniques using gp can induce homogeneous HA precipitation, enhance adhesion stability between PU and HA, and improve the inherent biological properties of PU. It indicated a great potential for use in tissue engineering applications, including auricular cartilage replacement and bone regeneration scaffolds.

Kaiser Manzoor

Jamia Millia Islamia, India

Title: Biopolymers in Remediation of Wastewater: A Sustainable Approach Towards Environmental Engineering

Biography:

Kaiser Manzoor born in Kashmir has received B.Sc. (Hons.) from Aligarh Muslim University in 2011 and completed M.Sc. Analytical Chemistry from the same university in 2013. He has expertise in chromatographic separation of amino acids, spectrophotometric determination of co, flame photometric determination of Na, K, Mg, analysis of a mixture of Cu & Co by spectrophotometry, M.Sc. IV semester seminar:Â capillary electrophoresis coupled with ICPMS for chemical speciation analysis. Presently competing his doctoral degree in Bio Remediation of Wastewater in Department of Chemistry Jamia Millia Islamia New Delhi, India. He authors a number of publications on the subject in various reputed journals of ACS and Elsevier

Abstract:

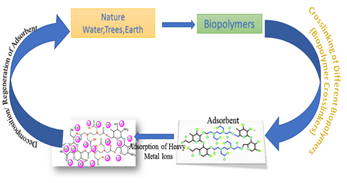

Heavy metal poisoning in living systems has led to serious concerns disturbing ecosystems due to industrialization in developing as well as in developed countries. Huge amounts of toxic substances majority of which consists of heavy metal ions, dyes etc. is discharged into the water bodies on daily basis. The heavy metals include copper, cadmium, lead, arsenic and mercury, all of which are highly toxic to all forms of living systems. Besides EU Regulation1881/2006/ΕU have proposed that for aquatic life the permissible limits of Hg, Cd, Pb is 0.5 mg/kg, 0.05 mg/kg, 0.30 mg/kg, respectively. Arsenic mainly discharged from the pesticide industries causes drowsiness, brain damage, peripheral neuropathy and hemorrhages in humans. Cadmium is used in electroplating industries and it is categorized as human carcinogen by International Agency for Research on Cancer. Inhalation of the cadmium containing dust causes vomiting, respiratory tract and kidney problems, abdominal cramps and pulmonary edema. Copper is essential in low concentrations and is present in two forms bound to ceroplasmin and free form which is involved in reducing oxidative stress. However, its excess leads to impairment of zinc homeostasis which in turn causes disruption of antioxidant enzyme function thereby increasing oxidative stress.

We have synthesized an adsorbent by simple esterification reaction by crosslinking carboxymethyl cellulose with chitosan using EDTA as crosslinker. Due to presence of the ample number of amine and hydroxyl groups the adsorption efficiency was increased sufficiently. A large number of evidences justify the strong chelation of the dipositive heavy metal ions by EDTA.Â

We have synthesized an adsorbent by simple esterification reaction by crosslinking carboxymethyl cellulose with chitosan using EDTA as crosslinker. Due to presence of the ample number of amine and hydroxyl groups the adsorption efficiency was increased sufficiently. A large number of evidences justify the strong chelation of the dipositive heavy metal ions by EDTA.Â

Â

Beste Balci

Kyoto University, Japan

Title: PEG-peptide based doxorubicin delivery systems

Time : 15:55-16:40

Biography:

Beste Balci graduated from the Department of Chemical Engineering at Izmir Institute of Technology. Then, she completed her MSc degree at the Biofunctional Materials Laboratory at the same institution under the supervision of Assistant Professor Ayben Top. During her MSc studies she has focused on the development of PEG-peptide based pH responsive drug delivery systems for cancer therapy and this study was financially supported by TUBITAK (The Scientific and Technological Research Council of Turkey) with a grant number of 112S554 during 2013-2016. Currently, she is a PhD. student at Kyoto University.

Abstract:

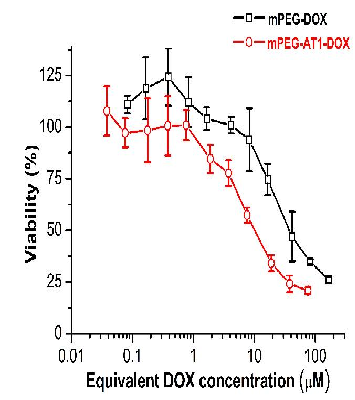

Statement of the Problem: pH responsive drug delivery systems (DDS) have been developed to increase therapeutic activity of the drug and to overcome multidrug resistance problem of cancer cells. One of the drawbacks of the DDS with pH sensitive moieties where drug molecules are hold via intermolecular interactions is considerable release of the cargo at physiological pH. Although chemically attaching the drug to the carrier molecule can minimize the drug release at neutral pH, these configurations suffer from slow release at acidic conditions as well. In this study, a pH responsive DDS containing both pH responsive functional groups and acid cleavable chemical bond between drug and carrier molecule was proposed. Methodology & Theoretical Orientation: mPEG-peptide based doxorubicin delivery system (mPEG-AT1-DOX) containing pH responsive histidines and hydrazone bond was developed and its performance was compared with peptide-free DDS, mPEG-DOX having hydrazone bond. Findings: Hydrodynamic diameters of mPEG-DOX were determined as 9 ± 0.5 and 7 ± 0.5 nm at pH 7.4 and pH 5.0, respectively. mPEG-AT1-DOX, on the other hand, exhibited a size distribution between 20 and 100 nm centered at about 40 nm at acidic pH much larger than its mean size at neutral pH measured as 12 ± 2 nm. Enhanced pH responsiveness of mPEG-AT1-DOX was also confirmed by the comparison of the percentage of DOX release values of both DDS evaluated at pH 7.4 and pH 5.0. Cytotoxicity of the DDS was assessed using A549 cell line. DOX equivalent absolute IC50 values were obtained as 1.8 ± 0.9, 40.3 ± 10.9, and 10.2 ± 1.4 µM for free DOX, mPEG-DOX, and mPEG-AT1-DOX, respectively. Conclusion & Significance: Superior pH sensitivity and cytotoxicity of mPEG-AT1-DOX indicated utilization of both pH responsive functional groups and acid cleavable chemical bond can be a promising approach in the design of DDS for cancer therapy.

RECHACHE Mustapha

University of Oran1 Ahmed Ben Bella. Algeria

Title: Elaboration of a lignocellulosic material for a comparative study of adsorption of micropollutants in aqueous solution

Biography:

Abstract:

Elaboration of a lignocellulosic material for a comparative study of adsorption of micropollutants in aqueous solution

Present study was consisted in the chemical treatment of raw timber sawdust (TS-OH)r by chemical agents (acid and base) for the comparative removal of two anionic dyes, namely, Thiazole Yellow (TY) and Bright Yellow (BY), from aqueous solutions. Batch experiments were performed to evaluate the influence of various operating conditions viz., pH, contact time, temperature, etc. on dyes removal efficiency. This results obtained from the Adsorption of the two dyes, was found to be endothermic with second-order rate kinetics, who followed the Langmuir isotherm. The monolayer saturation capacities are 1408.4507 and 140.845 mg g-1 for Thiazole Yellow and Bright Yellow respectively. Adsorption was favorably influenced by an increase in the temperature of the operation. The positive values of the change in entropy (DS0) and heat of adsorption (DH0); and the negative value of change in Gibbs free energy (DG0) indicate feasible and spontaneous adsorption of (TY and BY) on adsorbent. Desorption experiments with 1 M aqueous NaCl put into evidence that anionic dyes were completely desorbed from the matrices and the reusability of the (TS-OH)r chemically modify after three repeated cycles led to just a slight attenuation in its performance. These results show that chemical treatment of a low value by-product of the timber industry leads to an effective adsorbent.

- Biopolymers and Biodegradable Plastics

Location: 2

Session Introduction

Rifati Hanifa

University of Riau, Pekanbaru, Indonesia

Title: The Effects of Addition Graphene Oxide to The Mechanical Properties of Bioplastic Based on Sago Starch

Biography:

Abstract:

Bioplastic or degradable plastic is one of convensional plastic alternative which does not endanger for environmental. Making bioplastic can ease the process of plastic degradation inside the ground. Sago can be one of the base materials for bioplastic because it has high starch content. The general aims of this research are to know the effects of adding graphene oxide and stirring time to the mechanical properties (tensile strenght, elongation and modulus young), hidrophobicity, biodegradation and morphology of sago starch bioplastic. Bioplastic was synthesized by intercalation of starch solution, water, filler and plasticizer with combination graphene oxide 0% v/v, 5% v/v, 10% v/v, 15% v/v and combination stirring time 15 and 50 minutes. The results of this research showed that treatment by added of graphene oxide and stirring time contributed to the mechanical properties of bioplastic produced. The best result of bioplastic produced was 10% graph ene oxide and 50 minutes stirring time with value of tensile strenght 4,108 Mpa, elongation 11,528% and modulus young 34,854 Mpa. The result of sago starch bioplastic would degradation 78,9% about 8 days in natural way with value of hidrophobicity 68,571%. Microgaph analysis showed that stirring time affect filler distribution which is bioplastic with stirring time 15 minutes made filler distribution can not spread equally, it can be known by there is still has clots

Zayniddin K. Muhidinov

Institute of Academy of Sciences of the Tajikistan Republic

Title: Characterization of a polysaccharide from Eremurus hissaricus roots growing in Tajikistan

Time : 15:10-15:55

Biography:

Zayniddin K. Muhidinov obtained his University degree in Chemistry at the Tajik State University and a Ph.D. in Chemistry of Natural Compounds and Doctor of Science degree in Polymer Chemistry at Chemistry Institute of Academy of Sciences of the Tajikistan Republic. Dr. Muhidinov passed doctoral courses at the All India Institute of Medical Sciences, New Delhi, India in 1998-1999 and the Temple University, Philadelphia, PA USA in 2003. In last 14 years his group collaborating with USDA scientists in several projects pertaining to develop domestic agricultural byproducts into Drug Delivery Systems (DDS) for therapeutic purposes. His most recent project deals with the study of herbal biological active compounds. Professor Muhidinov is the author of a monograph; four chapters of the book (published by the American Chemical and Royal Societies) more than 290 scientific articles and abstracts, including 38 paper in peer reviewd journals, 10 patebts.

Abstract:

Statement of the Problem: Roots of medical plants are important resources of bioactive compounds including a polysaccharide, many of which, have been reported to possess various biological functions. Two types of water-soluble (WSP) and acid-soluble polysaccharides (ASP) with 23% and 8% yields, the molecular weight of 495 kDa and 179 kDa respectively were obtained from the roots of Eremurus hissaricus growing in Tajikistan in dormancy periods. The crude polysaccharides after deproteinization were purified by ion-exchange and gel filtration chromatography to obtain a homogeneous polysaccharide. The monosaccharide composition of WSP and ASP were analyzed by HPAEC-PAD. WSP was composed of D- mannose and D- glucose in 1.7:1 molar ratio. ASP content includes the pectic polysaccharide. IR spectra and analysis of 2D NMR analyses of WSP provide evidence that it has a backbone of (1→4)-linked ß-D-glucopyranosyl and ß-D-mannopyranosyl. The NMR and FTIR spectra of both crude and purified WSP has no differences. This fact probably indicates that WSP has no significant impurity. The carboxyl group of WSP is highly esterified. The NMR analyses of the ASP and deproteinated ASP polysaccharides suggest that the samples are composed of rhamnose, galactose or glucose, xylose, and arabinose, with partially methyl- and acetylated carboxyl groups, which may be consistent with a branched pectic rhamnogalacturonan. Unfortunately, monosaccharide analysis has not yet been performed on these samples. The NMR spectra of the ASP-S3 sample is similar to the other two, but it appears to lack resonances assignable to xylose. It is unclear what this means. The bands at 801 cm-1 in the FTIR of the ASP samples were characteristic of the a-pyranose configuration of sugar unit of the pectin polysaccharide, while the absorption in the region of 880-890 cm-1 confirms the presence of ß-pyranose configuration of another sugar residue in the WSP.

Fig. 1. Tuber roots of Eremurus Hissaricus (1&2) and schema for extraction (3), purification of WS- and AS- polysaccharides (4) and structural analysis (5).

- Biopolymers: Applications and Trends

Location: 4

Session Introduction

Fadi Ibrahim

Saad bin-alrabee alansari School Kuwait

Title: Smart Green Chemistry Synthesis of Microporous Material by Flow Injection method For CO2 capture

Biography:

Abstract:

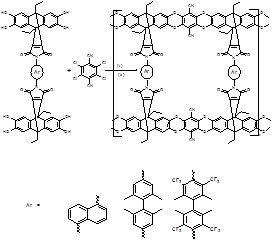

Carbon dioxide is thought to be one of the contributing factors in the rise of global warming. Consequently the discovery for an efficient and economically valuable gas capturing system is highly in demand. Therefore there have been various recent developments in creating new, efficient and adaptable gas capturing materials. Microporous organic based materials received great research efforts in the field of environmental related applications such as gas storage and separations due to their permanent porosity, low density (i.e. composed of light weight elements) and remarkable physicochemical stability. Three anthracene microporous polymers (AMPs)1,2 bridged by imide links were successfully prepared by conventional nucleophilic substitution reaction between different 9,10-dihydro-9,10-ethanoanthracenes and 2,3,5,6-tetrachlorophalonitrile as shown in Fig 1. AMPs display a BET surface area in the range of 711-796 m2 g–1, and adsorb reach to 1.70 wt. % H2 at 1.09 bar/77 K. The enhanced microporosity, in comparison to other organic microporous polymers originates from the macromolecular shape of framework, as dictated by the anthracene units, which helps to reduce intermolecular contact between the extended planar struts of the rigid framework. The impressive hydrogen adsorption capture of these materials verified by Horvath−Kawazoe (HK) and NLDFT analyses of low-pressure nitrogen adsorption data, which expected to be use in transportation as a source of green chemistry. A novel synthesis method for AMPs was done by Flow Injection System (FIS). This method has the advantage over conventional synthesis method as saving time-solvent and lowering synthesis cost of. Optimizing conditions (sample & reagent volumes, 0.1 ml/min flow rate, with 0.5 m coil length and 0.5 mm i.d) were used for increasing percentage yield as shown in Fig 2.

Keywords: Microporous, Anthracene, CO2, AMPs, Flow Injection System, Polymers, H2 storage applications.

Synthetic pathway toward the polyamide network AMP(5-7)s. Reagent and conditions: (i) K2CO3, and DMF (ii) 100 oC for 48h. The network polymer was washed with a variety of organic solvents

Synthetic pathway toward the polyamide network AMP(5-7)s. Reagent and conditions: (i) K2CO3, and DMF (ii) 100 oC for 48h. The network polymer was washed with a variety of organic solvents

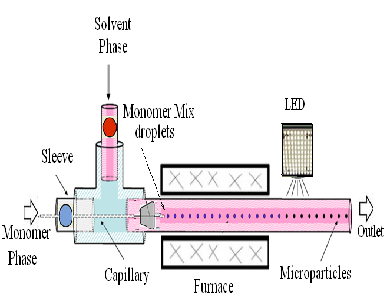

Schematic drawing of the capillary-based system for the production of simple AMPs microparticles using LED-Furnace system. Two-phase flow reactors that generation of the fluid segments and PTFE mixers (200 cm length, 0.5 mm I.D.) placed inside a temperature-controlled block (90oC) with application of an electric field to make fusion by lower the interfacial tension between droplets.

Cattaleeya Pattamaprom

Thammasat University Thailand

Title: The Effect of Branching Agent on the Processability and Mechanical Properties of Polylactic Acid/Natural Rubber Blown Film

Time : 14:05-14:50

Biography:

Dr. Cattaleeya Pattamaprom is currently the head of polymer and rubber technology center and an associate professor at the department of chemical engineering, Thammasat University, Thailand. She obtained her doctoral degree specialized on theoretical modeling of polymer rheology from the department of chemical engineering, University of Michigan, USA. Her research areas include rheology and theoretical modelling of polymer and rubber, polymer and rubber modification, polymer/rubber processing, composites and blends. Most recently, her research focuses on value adding and sustainable use and development of biopolymer and natural rubber products. With her background as a chemical engineer, another area of her expertise is on heat transfer, heat exchanger design and biodiesel

Abstract:

Polylactic acid (PLA) is currently known to be the cheapest and the most prevalent commercial bioplastic. However, its poor toughness and processability limited its applications in film blowing products. In this study, improvement in the toughness of PLA was investigated by blending with natural rubber (NR) with the aid of a plasticizer. The improvement in the bubble stability during film blowing process was investigated by using a peroxide branching agent (BA). The compound of PLA, NR and a branching agent (PLA/NR/BA) was prepared by reactive melt blending method. The parameters investigated are the PLA to NR ratio and the content of branching agent on the mechanical properties, processability, and morphology of the blend. The results indicated that NR could increase the tensile toughness and elongation at break of PLA blown films and the use of higher amount of branching agent could allow stable processing of PLA/NR blends at higher NR content. The reactions of branching agent with PLA and NR were verified by Fourier-transform infrared spectroscopy.

Walter Eevers

Walter Eevers Flemish Institute for technological research, Belgium

Title: Lignin valorization by making aromatic chemicals and materials

Biography:

Walter Eevers acts as director R&D for the Flemish Institute for technological research (VITO) and as visiting professor Polymer chemistry at Antwerp University. After obtaining his PhD and MBA he worked for 20 years as director R&D and Innovation at Nitto. Already during his private career he started a research group in biobased polymer developments for industrial and medical applications. He has over 30 publications and patents on innovations in polymer and materials developments. Furthermore he has been involved in several spin off companies in innovative technologies derived from VITO’s research activities. Recently he has set up a new research group dedicated to incorporation of lignin based monomers and oligomers for materials developments replacing fossil based aromatic building blocks; furthermore he has been one of the founding father of the CO2 Value Europe association that endeavors the full acceptance of the utilization of CO2 a valuable building block for innovative chemistry.

Abstract:

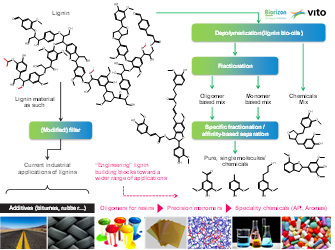

Statement of the Problem: BTX (benzene, toluene, Xylene) represent a massive 120B$ and 14.2Mtons market of numerous chemicals and products used worldwide. The fight against climate change has convinced many brand-owners to push for more renewables to be incorporated in their product ranges. Furthermore the strong growth of shale gas as energy and feedstock source has demonstrated that the traditional C3 feedstock for aromatics is reduced at the origin. The need for alternative sources for this multiple of products is driven as well by supply as demand. The purpose of this study is to describe the potential of lignin as feedstock for novel polymers and foams. Methodology & Theoretical Orientation: Starting from the insight in potential lignin sources, the variations in de-polymerization technologies available, a set of functionalized monomers and oligomers is prepared as starting point for the polymerization process. Additional introduction of epoxide groups or the introduction of lignin as a polyol in the urethane approach lead to new structures. The presence of residual functional groups on the lignin segments contribute to variations in the physical mechanical properties of the polymers. Simultaneously with the technical evaluation of the potential innovative materials for different applications an economic analysis of these material developments is integrated in the study in order to safeguard the potential introduction of the innovative technologies in existing applications of aromatic polymers. Conclusion & Significance: The widespread availability of lignin in many different places in the world is creating great opportunity to simultaneously develop new materials without dependency on oil as a feedstock but also as a contribution to fighting climate change. Simultaneously a complete new value chain is being developed creating great new business opportunities for new actors in the world.

Image

Fig: Development strategies for demand driven innovation with lignin based feedstock towards innovative materials