Fadi Ibrahim

Saad bin-alrabee alansari School Kuwait

Title: Smart Green Chemistry Synthesis of Microporous Material by Flow Injection method For CO2 capture

Biography

Biography: Fadi Ibrahim

Abstract

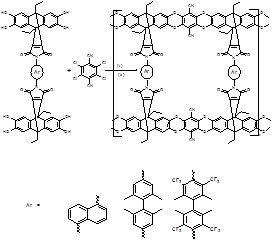

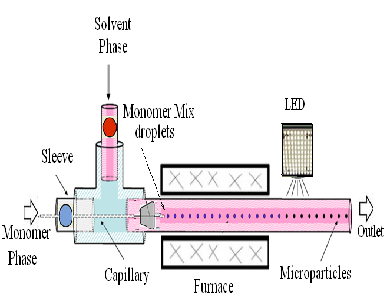

Carbon dioxide is thought to be one of the contributing factors in the rise of global warming. Consequently the discovery for an efficient and economically valuable gas capturing system is highly in demand. Therefore there have been various recent developments in creating new, efficient and adaptable gas capturing materials. Microporous organic based materials received great research efforts in the field of environmental related applications such as gas storage and separations due to their permanent porosity, low density (i.e. composed of light weight elements) and remarkable physicochemical stability. Three anthracene microporous polymers (AMPs)1,2 bridged by imide links were successfully prepared by conventional nucleophilic substitution reaction between different 9,10-dihydro-9,10-ethanoanthracenes and 2,3,5,6-tetrachlorophalonitrile as shown in Fig 1. AMPs display a BET surface area in the range of 711-796 m2 g–1, and adsorb reach to 1.70 wt. % H2 at 1.09 bar/77 K. The enhanced microporosity, in comparison to other organic microporous polymers originates from the macromolecular shape of framework, as dictated by the anthracene units, which helps to reduce intermolecular contact between the extended planar struts of the rigid framework. The impressive hydrogen adsorption capture of these materials verified by Horvath−Kawazoe (HK) and NLDFT analyses of low-pressure nitrogen adsorption data, which expected to be use in transportation as a source of green chemistry. A novel synthesis method for AMPs was done by Flow Injection System (FIS). This method has the advantage over conventional synthesis method as saving time-solvent and lowering synthesis cost of. Optimizing conditions (sample & reagent volumes, 0.1 ml/min flow rate, with 0.5 m coil length and 0.5 mm i.d) were used for increasing percentage yield as shown in Fig 2.

Keywords: Microporous, Anthracene, CO2, AMPs, Flow Injection System, Polymers, H2 storage applications.

Synthetic pathway toward the polyamide network AMP(5-7)s. Reagent and conditions: (i) K2CO3, and DMF (ii) 100 oC for 48h. The network polymer was washed with a variety of organic solvents

Synthetic pathway toward the polyamide network AMP(5-7)s. Reagent and conditions: (i) K2CO3, and DMF (ii) 100 oC for 48h. The network polymer was washed with a variety of organic solvents

Schematic drawing of the capillary-based system for the production of simple AMPs microparticles using LED-Furnace system. Two-phase flow reactors that generation of the fluid segments and PTFE mixers (200 cm length, 0.5 mm I.D.) placed inside a temperature-controlled block (90oC) with application of an electric field to make fusion by lower the interfacial tension between droplets.