Day 3 :

Keynote Forum

Dr. Xiaoqing Liu

Full professor in Ningbo Institute of Materials Technology and Engineering (NIMTE

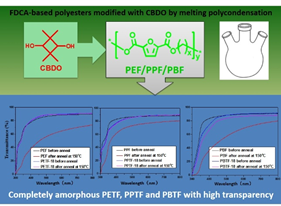

Keynote: Synthesis of Bio-based Polyesters from 2,5-furandicarboxylic acid (2,5-FDCA): From Completely Amorphous to High Crystallinity

Time : TBA

Biography:

Dr. Xiaoqing Liu is a full professor in Ningbo Institute of Materials Technology and Engineering (NIMTE), Chinese Academy of Sciences (CAS). He obtained his Ph.D in polymer chemistry and physics from Institute of Chemistry, CAS, in 2007. From 2008-2009, he worked as a postdoc in Nanyang Technological University (Singapore) and Washington State University (USA). In Oct. 2009, he began to work as an associate professor in NIMTE and was promoted to a full professor in 2013. His research work was focused on the synthesis of bio-based polymers and composites, including bio-based high performance epoxy and polybenzoxazine, bio-based polyesters from 2,5-furandicarboxylic acid (FDCA). Up to now, he has published 60+ peer-reviewed SCI papers in the journal of Green Chemistry, ChemSusChem, Journal of Materials Chemistry A and Polymer et al. and held 30+ granted patents in the field of bio-based polymers.

Abstract:

Due to the diminishing crude oil reserve and worsening environmental pollution, more and more attention has been paid on the synthesis of polymers derived from renewable resources. However, the thermal and mechanical properties of current bio-based polymers are still subjects to be improved when compared with the petroleum-based engineering plastics like poly(ethylene terephthalate) (PET) and polycarbonate (PC). The lack of aromatic or rigid segments in their molecular architectures should be responsible for the relatively low performance. 2,5-furandicarboxylic acid (FDCA) is a promising bio-based platform chemical, which has been referred to as a “sleeping giants” by DuPont and DSM due to its potential as the bio-based substitute for terephthalate (TPA). The FDCA-based polyester, poly (ethylene 2, 5-furandicarboxylate) (PEF) demonstrats similar mechanical and thermal properties as well as better barrier properties when compare with its petroleum-based counterpart PET. However, the poor crystallizability of PEF severely limits its application fields, especially when the high transparent and heat-resistant properties, or the high crystallinity was required. In our work, several novel cyclic diols, including 1, 4-cyclohexanedimethanol (CHDM) and 2, 2, 4, 4-tetramethyl-1, 3-cyclobutanediol (CBDO), were employed as the monomer or co-monomer to polymerize with FDCA and the high molecular weight polyesters were synthesized. Results showed that these bio-based polyesters could be varied from completely amorphous to high crystallinity, which has the potential to be used as high transparent packaging materials or polyester engineering plastics, respectively. Based on our results, the bio-based substitute for PET with better comprehensive performance could be developed

- Advanced Biopolymers

Location: "Hyatt Regency Osaka, Osaka, Japan 1-13-11 Nanko-Kita Suminoe-Ku 559-0034 Osaka Japan"

Session Introduction

Jin Huang

Southwest University, China

Title: Focus on surface modification of cellulose nanocrystals to enhance mechanical properties of bio-based polyesters

Biography:

Professor Dr. Jin Huang is affiliated with School of Chemistry and Chemical Engineering, Southwest University, China. He received the PhD from Wuhan University, and completed postdoctoral research in Institute of Chemistry, Chinese Academy of Sciences. Thereafter, he has worked in Wuhan University of Technology from 2005 to 2015, and carried out some research in Grenoble Institute of Technology in this period. The one of his research interests focuses on “Developing chemical and physical methodology and technologies to manufacturing green materials from biomass resources”, and he has worked on the preparation and evaluation of bioplastics, composites and nanocomposites using natural polymers including cellulose, chitin and chitosan, starch, plant proteins etc., and explored some advanced applications. Especially, the surface chemical modification and new nanocomposites of cellulose nanocrystals are the main topics. Up to now, he has authored and co-authored more than 140 peer-reviewed journal publications, 1 monograph and 7 book chapters, over 40 granted patents, and many conference papers/presentations

Abstract:

Due to increasing concern about the environmental protection and the substitute of fossil resources, the development and applications of sustainable materials derived from biomass resources have aroused great interest. Especially, the bio-based polyester including poly(lactic acid) (PLA), poly(butylene succinate) (PBS), poly(3-hydroxybutyrate-co-4-hydroxybutyrate) (P(3,4)HB) etc., have been extensively attempted to develop environment-friendly materials and products. Furthermore, it is highlighted that the unique properties of nano-filler contribute to the enhancement of mechanical performances for polymeric materials. In comparison with inorganic nano-fillers, cellulose nanocrystal exhibits many advantages including renewability, biodegradability, biocompatibility, high specific modulus and so on, and shows a rod-like morphology and highly crystalline. As well known, the interface between nano-fillers and polymer matrix is the key issue to determine stress transferring among components, organization of polymer matrix and distribution of nano-fillers. Moreover, the strategies of small molecule-conjugation and polymer-grafting towards cellulose nanocrystals have been applied to regulate surface physicochemical properties, and hence to improve interfacial interaction and even formed chemical linkage between nano-filler and matrix, which gave high mechanical performances for the nanocomposites of cellulose nanocrystal-filled bio-based polyesters. For the bio-based polyester matrix, surface acetylation of cellulose nanocrystals was conducive to promoting their interfacial compatibility with hydrophobic polyester matrix together with an enhancement in mechanical properties of the as-prepared nanocomposites. With an increase of surface acetylation degree, the discrepancy in the surface energy between cellulose nanocrystal surface and polyester matrix gradually decreased, resulting in better affinity and stronger interaction between two components. Hence, homogeneous distribution of acetylated cellulose nanocrystals in polyester matrix was improved, which contributed to optimized reinforcement cellulose nanocrystal with less loss of elongation of the nanocomposites.

Ryan W. Davis

As a Principal Member, Sandia National Laboratories

Title: Cultivation and utilization of cyanobacterial exopolysaccharide for production of biobased polymers

Time : 11:50-12:35

Biography:

As a Principal Member of Technical Staff at Sandia National Laboratories, Ryan’s research has focused on science and technology for production of biobased commodities from renewable feedstocks using nonarable land and non-freshwater resources. Ryan recieved his Ph.D. in Physical Chemistry from the University of New Mexico and completed post-doctoral studies at Sandia Laboratories in New Mexico and California. Ryan has published >25 articles in peer-reviewed journals and is director of the Sandia Algae Raceway Testbed Facility

Abstract:

Development of polycultures has been identified as a potential means for overcoming several challenges facing scale-up of algae-based commodities which can displace petroleum but do not compete with food production. In this presentation, we describe findings from our recent studies on cultivation of a marine cyanobacterial consortium in open algae raceways, and downstream conversion to bioplastic. In the consortium, three distinct cyanobacterial cultivars were combined to provide nitrogen fixation, photoprotection, and high rates of secretion of extracellular polysaccharides in support of a long-term bioproduct ‘milking’ strategy. Following lab-scale investigations of various combinations of the individial cultivars to identify optimal algae raceway inoculation and maintenance strategies, the best performing consortia were successfully cultivated in pilot-scale algae raceways for >120 days. The growth trials indicated bioproduct concentrations >2 g/L consisting primarily of a variety of C5 and C6 monosugars which were recovered using a low-cost semi-continuous harvesting strategy. In addition to the remarkable stability of the consortium in open cultivation, measurements of culture density time course indicated insignificantly different log-phase specific growth rates at different levels of nitrate or carbon dioxide addition, which should have significant techno-economic and sustainability impacts for commercialization. Following recovery of the biomass and exopolymer, generation of cyanobacterial-derived bioplastic was demonstrated and performance characteristics were found to be similar to common biobased plastics, such as PLA. Initial technoeconomic analysis based on the product yield and corresponding biomass production, harvesting, and conversion costs indicate an Nth-plant model finished product cost of $600/ton.

- Biopolymers: Biomedical and Environmental Applications

Location: "Hyatt Regency Osaka, Osaka, Japan 1-13-11 Nanko-Kita Suminoe-Ku 559-0034 Osaka Japan"

Session Introduction

Seol-Ha

Seoul National University, Korea

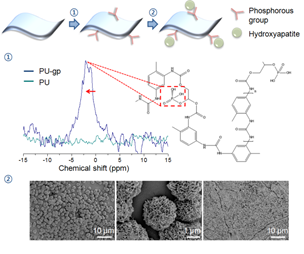

Title: Biomimetic Coating of Hydroxyapatite on Glycerol Phosphate-Conjugated Polyurethane via Mineralization

Biography:

Seol-Ha Jeong fabricated hyaluronic acid based nanocomposite hydrogels for various biomedical applications. She has applied in-situ precipitation process to hyaluronic acid hydrogel for hydroxyapatite precipitation within the gels. Her evaluation evaluation based on in vitro and in vivo models creates new pathways for improving healthcare, including wrinkle improvement and wound dressing applications. She is also interested in polyurethane based composite systems with high functionality

Abstract:

Statements of Problem: Polyurethane (PU) based biopolymers have been widely used in various medical fields due to a highly porous structure and controllable mechanical properties. However, it lacks of biocompatibility compared to natural polymers. In order to improve the biological properties, hydroxyapatite (HA) has been widely used for coating on PU. However, as PU has no specific sites for interactions with hydrophilic coating layers, coating stability had not been achieved without any further processes. In this study, glycerol phosphate (gp) was introduced as a new conjugate to improve HA coating stability on PU.

Orientation: PU-gp-HA was fabricated, following 2 step; (1) glycerol phosphate conjugation and (2) HA mineralization. PU-gp was fabricated through foaming reaction. During this process, gp was conjugated with TDI based PU prepolymer. Then, PU-gp was immersed in concentrated simulated body fluid (SBF) solution to induce HA mineralization on the surface of PU-gp.

Findings: gp was conjugated through urethane bonding with PU. Phosphate functional groups acted as nucleation sites for amorphous calcium phosphate in SBF solution to be anchored. Phosphate groups not only promoted HA nucleation, but also provided robust interface between PU and HA from exterior impacts. Most HA was detached from pure PU while large portion of HA remained on PU-gp after sonication. Filopodia of fibroblasts were well spread on PU-gp and PU-gp-HA than pure PU due to hydrophilic phosphate groups and bioactive HA. HA also activated fibroblasts’ proliferation remarkably from 3 to 5 day of culturing time.

Significance: This study demonstrated that elastomer modifying techniques using gp can induce homogeneous HA precipitation, enhance adhesion stability between PU and HA, and improve the inherent biological properties of PU. It indicated a great potential for use in tissue engineering applications, including auricular cartilage replacement and bone regeneration scaffolds.

Kaiser Manzoor

Jamia Millia Islamia, India

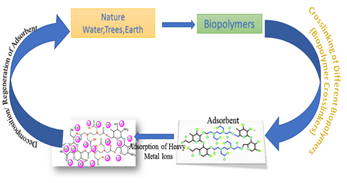

Title: Biopolymers in Remediation of Wastewater: A Sustainable Approach Towards Environmental Engineering

Biography:

Kaiser Manzoor born in Kashmir has received B.Sc. (Hons.) from Aligarh Muslim University in 2011 and completed M.Sc. Analytical Chemistry from the same university in 2013. He has expertise in chromatographic separation of amino acids, spectrophotometric determination of co, flame photometric determination of Na, K, Mg, analysis of a mixture of Cu & Co by spectrophotometry, M.Sc. IV semester seminar:Â capillary electrophoresis coupled with ICPMS for chemical speciation analysis. Presently competing his doctoral degree in Bio Remediation of Wastewater in Department of Chemistry Jamia Millia Islamia New Delhi, India. He authors a number of publications on the subject in various reputed journals of ACS and Elsevier

Abstract:

Heavy metal poisoning in living systems has led to serious concerns disturbing ecosystems due to industrialization in developing as well as in developed countries. Huge amounts of toxic substances majority of which consists of heavy metal ions, dyes etc. is discharged into the water bodies on daily basis. The heavy metals include copper, cadmium, lead, arsenic and mercury, all of which are highly toxic to all forms of living systems. Besides EU Regulation1881/2006/ΕU have proposed that for aquatic life the permissible limits of Hg, Cd, Pb is 0.5 mg/kg, 0.05 mg/kg, 0.30 mg/kg, respectively. Arsenic mainly discharged from the pesticide industries causes drowsiness, brain damage, peripheral neuropathy and hemorrhages in humans. Cadmium is used in electroplating industries and it is categorized as human carcinogen by International Agency for Research on Cancer. Inhalation of the cadmium containing dust causes vomiting, respiratory tract and kidney problems, abdominal cramps and pulmonary edema. Copper is essential in low concentrations and is present in two forms bound to ceroplasmin and free form which is involved in reducing oxidative stress. However, its excess leads to impairment of zinc homeostasis which in turn causes disruption of antioxidant enzyme function thereby increasing oxidative stress.

We have synthesized an adsorbent by simple esterification reaction by crosslinking carboxymethyl cellulose with chitosan using EDTA as crosslinker. Due to presence of the ample number of amine and hydroxyl groups the adsorption efficiency was increased sufficiently. A large number of evidences justify the strong chelation of the dipositive heavy metal ions by EDTA.Â

We have synthesized an adsorbent by simple esterification reaction by crosslinking carboxymethyl cellulose with chitosan using EDTA as crosslinker. Due to presence of the ample number of amine and hydroxyl groups the adsorption efficiency was increased sufficiently. A large number of evidences justify the strong chelation of the dipositive heavy metal ions by EDTA.Â

Â

Beste Balci

Kyoto University, Japan

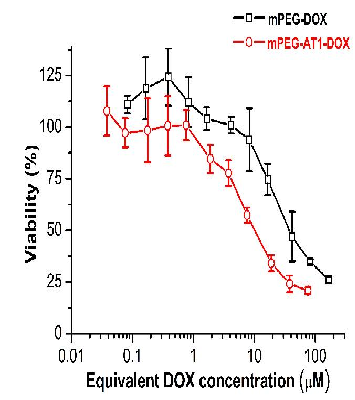

Title: PEG-peptide based doxorubicin delivery systems

Time : 15:55-16:40

Biography:

Beste Balci graduated from the Department of Chemical Engineering at Izmir Institute of Technology. Then, she completed her MSc degree at the Biofunctional Materials Laboratory at the same institution under the supervision of Assistant Professor Ayben Top. During her MSc studies she has focused on the development of PEG-peptide based pH responsive drug delivery systems for cancer therapy and this study was financially supported by TUBITAK (The Scientific and Technological Research Council of Turkey) with a grant number of 112S554 during 2013-2016. Currently, she is a PhD. student at Kyoto University.

Abstract:

Statement of the Problem: pH responsive drug delivery systems (DDS) have been developed to increase therapeutic activity of the drug and to overcome multidrug resistance problem of cancer cells. One of the drawbacks of the DDS with pH sensitive moieties where drug molecules are hold via intermolecular interactions is considerable release of the cargo at physiological pH. Although chemically attaching the drug to the carrier molecule can minimize the drug release at neutral pH, these configurations suffer from slow release at acidic conditions as well. In this study, a pH responsive DDS containing both pH responsive functional groups and acid cleavable chemical bond between drug and carrier molecule was proposed. Methodology & Theoretical Orientation: mPEG-peptide based doxorubicin delivery system (mPEG-AT1-DOX) containing pH responsive histidines and hydrazone bond was developed and its performance was compared with peptide-free DDS, mPEG-DOX having hydrazone bond. Findings: Hydrodynamic diameters of mPEG-DOX were determined as 9 ± 0.5 and 7 ± 0.5 nm at pH 7.4 and pH 5.0, respectively. mPEG-AT1-DOX, on the other hand, exhibited a size distribution between 20 and 100 nm centered at about 40 nm at acidic pH much larger than its mean size at neutral pH measured as 12 ± 2 nm. Enhanced pH responsiveness of mPEG-AT1-DOX was also confirmed by the comparison of the percentage of DOX release values of both DDS evaluated at pH 7.4 and pH 5.0. Cytotoxicity of the DDS was assessed using A549 cell line. DOX equivalent absolute IC50 values were obtained as 1.8 ± 0.9, 40.3 ± 10.9, and 10.2 ± 1.4 µM for free DOX, mPEG-DOX, and mPEG-AT1-DOX, respectively. Conclusion & Significance: Superior pH sensitivity and cytotoxicity of mPEG-AT1-DOX indicated utilization of both pH responsive functional groups and acid cleavable chemical bond can be a promising approach in the design of DDS for cancer therapy.

RECHACHE Mustapha

University of Oran1 Ahmed Ben Bella. Algeria

Title: Elaboration of a lignocellulosic material for a comparative study of adsorption of micropollutants in aqueous solution

Biography:

Abstract:

Elaboration of a lignocellulosic material for a comparative study of adsorption of micropollutants in aqueous solution

Present study was consisted in the chemical treatment of raw timber sawdust (TS-OH)r by chemical agents (acid and base) for the comparative removal of two anionic dyes, namely, Thiazole Yellow (TY) and Bright Yellow (BY), from aqueous solutions. Batch experiments were performed to evaluate the influence of various operating conditions viz., pH, contact time, temperature, etc. on dyes removal efficiency. This results obtained from the Adsorption of the two dyes, was found to be endothermic with second-order rate kinetics, who followed the Langmuir isotherm. The monolayer saturation capacities are 1408.4507 and 140.845 mg g-1 for Thiazole Yellow and Bright Yellow respectively. Adsorption was favorably influenced by an increase in the temperature of the operation. The positive values of the change in entropy (DS0) and heat of adsorption (DH0); and the negative value of change in Gibbs free energy (DG0) indicate feasible and spontaneous adsorption of (TY and BY) on adsorbent. Desorption experiments with 1 M aqueous NaCl put into evidence that anionic dyes were completely desorbed from the matrices and the reusability of the (TS-OH)r chemically modify after three repeated cycles led to just a slight attenuation in its performance. These results show that chemical treatment of a low value by-product of the timber industry leads to an effective adsorbent.

- Biopolymers and Biodegradable Plastics

Location: 2

Session Introduction

Rifati Hanifa

University of Riau, Pekanbaru, Indonesia

Title: The Effects of Addition Graphene Oxide to The Mechanical Properties of Bioplastic Based on Sago Starch

Biography:

Abstract:

Bioplastic or degradable plastic is one of convensional plastic alternative which does not endanger for environmental. Making bioplastic can ease the process of plastic degradation inside the ground. Sago can be one of the base materials for bioplastic because it has high starch content. The general aims of this research are to know the effects of adding graphene oxide and stirring time to the mechanical properties (tensile strenght, elongation and modulus young), hidrophobicity, biodegradation and morphology of sago starch bioplastic. Bioplastic was synthesized by intercalation of starch solution, water, filler and plasticizer with combination graphene oxide 0% v/v, 5% v/v, 10% v/v, 15% v/v and combination stirring time 15 and 50 minutes. The results of this research showed that treatment by added of graphene oxide and stirring time contributed to the mechanical properties of bioplastic produced. The best result of bioplastic produced was 10% graph ene oxide and 50 minutes stirring time with value of tensile strenght 4,108 Mpa, elongation 11,528% and modulus young 34,854 Mpa. The result of sago starch bioplastic would degradation 78,9% about 8 days in natural way with value of hidrophobicity 68,571%. Microgaph analysis showed that stirring time affect filler distribution which is bioplastic with stirring time 15 minutes made filler distribution can not spread equally, it can be known by there is still has clots

Zayniddin K. Muhidinov

Institute of Academy of Sciences of the Tajikistan Republic

Title: Characterization of a polysaccharide from Eremurus hissaricus roots growing in Tajikistan

Time : 15:10-15:55

Biography:

Zayniddin K. Muhidinov obtained his University degree in Chemistry at the Tajik State University and a Ph.D. in Chemistry of Natural Compounds and Doctor of Science degree in Polymer Chemistry at Chemistry Institute of Academy of Sciences of the Tajikistan Republic. Dr. Muhidinov passed doctoral courses at the All India Institute of Medical Sciences, New Delhi, India in 1998-1999 and the Temple University, Philadelphia, PA USA in 2003. In last 14 years his group collaborating with USDA scientists in several projects pertaining to develop domestic agricultural byproducts into Drug Delivery Systems (DDS) for therapeutic purposes. His most recent project deals with the study of herbal biological active compounds. Professor Muhidinov is the author of a monograph; four chapters of the book (published by the American Chemical and Royal Societies) more than 290 scientific articles and abstracts, including 38 paper in peer reviewd journals, 10 patebts.

Abstract:

Statement of the Problem: Roots of medical plants are important resources of bioactive compounds including a polysaccharide, many of which, have been reported to possess various biological functions. Two types of water-soluble (WSP) and acid-soluble polysaccharides (ASP) with 23% and 8% yields, the molecular weight of 495 kDa and 179 kDa respectively were obtained from the roots of Eremurus hissaricus growing in Tajikistan in dormancy periods. The crude polysaccharides after deproteinization were purified by ion-exchange and gel filtration chromatography to obtain a homogeneous polysaccharide. The monosaccharide composition of WSP and ASP were analyzed by HPAEC-PAD. WSP was composed of D- mannose and D- glucose in 1.7:1 molar ratio. ASP content includes the pectic polysaccharide. IR spectra and analysis of 2D NMR analyses of WSP provide evidence that it has a backbone of (1→4)-linked ß-D-glucopyranosyl and ß-D-mannopyranosyl. The NMR and FTIR spectra of both crude and purified WSP has no differences. This fact probably indicates that WSP has no significant impurity. The carboxyl group of WSP is highly esterified. The NMR analyses of the ASP and deproteinated ASP polysaccharides suggest that the samples are composed of rhamnose, galactose or glucose, xylose, and arabinose, with partially methyl- and acetylated carboxyl groups, which may be consistent with a branched pectic rhamnogalacturonan. Unfortunately, monosaccharide analysis has not yet been performed on these samples. The NMR spectra of the ASP-S3 sample is similar to the other two, but it appears to lack resonances assignable to xylose. It is unclear what this means. The bands at 801 cm-1 in the FTIR of the ASP samples were characteristic of the a-pyranose configuration of sugar unit of the pectin polysaccharide, while the absorption in the region of 880-890 cm-1 confirms the presence of ß-pyranose configuration of another sugar residue in the WSP.

Fig. 1. Tuber roots of Eremurus Hissaricus (1&2) and schema for extraction (3), purification of WS- and AS- polysaccharides (4) and structural analysis (5).

- Biopolymers: Applications and Trends

Location: 4

Session Introduction

Fadi Ibrahim

Saad bin-alrabee alansari School Kuwait

Title: Smart Green Chemistry Synthesis of Microporous Material by Flow Injection method For CO2 capture

Biography:

Abstract:

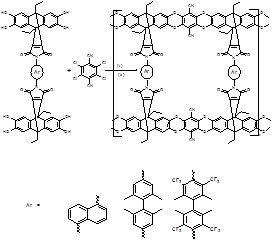

Carbon dioxide is thought to be one of the contributing factors in the rise of global warming. Consequently the discovery for an efficient and economically valuable gas capturing system is highly in demand. Therefore there have been various recent developments in creating new, efficient and adaptable gas capturing materials. Microporous organic based materials received great research efforts in the field of environmental related applications such as gas storage and separations due to their permanent porosity, low density (i.e. composed of light weight elements) and remarkable physicochemical stability. Three anthracene microporous polymers (AMPs)1,2 bridged by imide links were successfully prepared by conventional nucleophilic substitution reaction between different 9,10-dihydro-9,10-ethanoanthracenes and 2,3,5,6-tetrachlorophalonitrile as shown in Fig 1. AMPs display a BET surface area in the range of 711-796 m2 g–1, and adsorb reach to 1.70 wt. % H2 at 1.09 bar/77 K. The enhanced microporosity, in comparison to other organic microporous polymers originates from the macromolecular shape of framework, as dictated by the anthracene units, which helps to reduce intermolecular contact between the extended planar struts of the rigid framework. The impressive hydrogen adsorption capture of these materials verified by Horvath−Kawazoe (HK) and NLDFT analyses of low-pressure nitrogen adsorption data, which expected to be use in transportation as a source of green chemistry. A novel synthesis method for AMPs was done by Flow Injection System (FIS). This method has the advantage over conventional synthesis method as saving time-solvent and lowering synthesis cost of. Optimizing conditions (sample & reagent volumes, 0.1 ml/min flow rate, with 0.5 m coil length and 0.5 mm i.d) were used for increasing percentage yield as shown in Fig 2.

Keywords: Microporous, Anthracene, CO2, AMPs, Flow Injection System, Polymers, H2 storage applications.

Synthetic pathway toward the polyamide network AMP(5-7)s. Reagent and conditions: (i) K2CO3, and DMF (ii) 100 oC for 48h. The network polymer was washed with a variety of organic solvents

Synthetic pathway toward the polyamide network AMP(5-7)s. Reagent and conditions: (i) K2CO3, and DMF (ii) 100 oC for 48h. The network polymer was washed with a variety of organic solvents

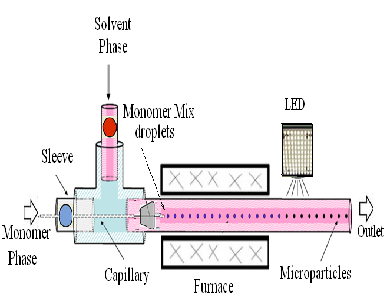

Schematic drawing of the capillary-based system for the production of simple AMPs microparticles using LED-Furnace system. Two-phase flow reactors that generation of the fluid segments and PTFE mixers (200 cm length, 0.5 mm I.D.) placed inside a temperature-controlled block (90oC) with application of an electric field to make fusion by lower the interfacial tension between droplets.

Cattaleeya Pattamaprom

Thammasat University Thailand

Title: The Effect of Branching Agent on the Processability and Mechanical Properties of Polylactic Acid/Natural Rubber Blown Film

Time : 14:05-14:50

Biography:

Dr. Cattaleeya Pattamaprom is currently the head of polymer and rubber technology center and an associate professor at the department of chemical engineering, Thammasat University, Thailand. She obtained her doctoral degree specialized on theoretical modeling of polymer rheology from the department of chemical engineering, University of Michigan, USA. Her research areas include rheology and theoretical modelling of polymer and rubber, polymer and rubber modification, polymer/rubber processing, composites and blends. Most recently, her research focuses on value adding and sustainable use and development of biopolymer and natural rubber products. With her background as a chemical engineer, another area of her expertise is on heat transfer, heat exchanger design and biodiesel

Abstract:

Polylactic acid (PLA) is currently known to be the cheapest and the most prevalent commercial bioplastic. However, its poor toughness and processability limited its applications in film blowing products. In this study, improvement in the toughness of PLA was investigated by blending with natural rubber (NR) with the aid of a plasticizer. The improvement in the bubble stability during film blowing process was investigated by using a peroxide branching agent (BA). The compound of PLA, NR and a branching agent (PLA/NR/BA) was prepared by reactive melt blending method. The parameters investigated are the PLA to NR ratio and the content of branching agent on the mechanical properties, processability, and morphology of the blend. The results indicated that NR could increase the tensile toughness and elongation at break of PLA blown films and the use of higher amount of branching agent could allow stable processing of PLA/NR blends at higher NR content. The reactions of branching agent with PLA and NR were verified by Fourier-transform infrared spectroscopy.

Walter Eevers

Walter Eevers Flemish Institute for technological research, Belgium

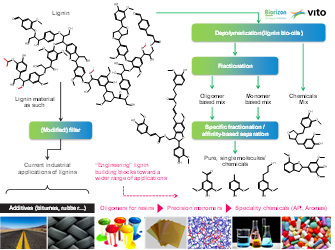

Title: Lignin valorization by making aromatic chemicals and materials

Biography:

Walter Eevers acts as director R&D for the Flemish Institute for technological research (VITO) and as visiting professor Polymer chemistry at Antwerp University. After obtaining his PhD and MBA he worked for 20 years as director R&D and Innovation at Nitto. Already during his private career he started a research group in biobased polymer developments for industrial and medical applications. He has over 30 publications and patents on innovations in polymer and materials developments. Furthermore he has been involved in several spin off companies in innovative technologies derived from VITO’s research activities. Recently he has set up a new research group dedicated to incorporation of lignin based monomers and oligomers for materials developments replacing fossil based aromatic building blocks; furthermore he has been one of the founding father of the CO2 Value Europe association that endeavors the full acceptance of the utilization of CO2 a valuable building block for innovative chemistry.

Abstract:

Statement of the Problem: BTX (benzene, toluene, Xylene) represent a massive 120B$ and 14.2Mtons market of numerous chemicals and products used worldwide. The fight against climate change has convinced many brand-owners to push for more renewables to be incorporated in their product ranges. Furthermore the strong growth of shale gas as energy and feedstock source has demonstrated that the traditional C3 feedstock for aromatics is reduced at the origin. The need for alternative sources for this multiple of products is driven as well by supply as demand. The purpose of this study is to describe the potential of lignin as feedstock for novel polymers and foams. Methodology & Theoretical Orientation: Starting from the insight in potential lignin sources, the variations in de-polymerization technologies available, a set of functionalized monomers and oligomers is prepared as starting point for the polymerization process. Additional introduction of epoxide groups or the introduction of lignin as a polyol in the urethane approach lead to new structures. The presence of residual functional groups on the lignin segments contribute to variations in the physical mechanical properties of the polymers. Simultaneously with the technical evaluation of the potential innovative materials for different applications an economic analysis of these material developments is integrated in the study in order to safeguard the potential introduction of the innovative technologies in existing applications of aromatic polymers. Conclusion & Significance: The widespread availability of lignin in many different places in the world is creating great opportunity to simultaneously develop new materials without dependency on oil as a feedstock but also as a contribution to fighting climate change. Simultaneously a complete new value chain is being developed creating great new business opportunities for new actors in the world.

Image

Fig: Development strategies for demand driven innovation with lignin based feedstock towards innovative materials

- Biopolymers from Renewable Resources

Location: 1

Session Introduction

Yinghao Fu

Huaqiao University,China

Title: Facile tailoring the morphology and water-solubility of chitosan

Biography:

Congming Xiao has completed his PhD from Zhejiang University. He is a professor of College of Material Science and Engineering of Huaqiao University. He has published more than 50 papers in reputed journals

Abstract:

The solubility of chitosan depended on its morphology mainly when its chemical structure was fixed. In viewing of this, we intended to modulate the water-solubility through tuning its morphology. Both the entanglement and crystalline degrees of chitosan could be varied through a common dissolution and precipitation processes, which resulted in the change of the water-solubility of chotosan accordingly. Several possible morphology models were presented for various samples obtained by simply changing the amount of solvents and precipitants. As a result, chitosan was able to be dissolved in water in absence of acid.

Eva-Marieke Lems

University of Natural Resources Austria

Title: Reinforcing Effect of Poly-furfurylalcohol on Freeze-dried Microfibrillated Cellulose Foams

Biography:

Eva-Marieke Lems received her Master degree in "Biomaterials Science and Technology" from BOKU University (Vienna) in 2017. Now she is doing her PhD with the entitled topic "Lignocellulosic materials and their application possibilities " which is supervised by Prof. Wolfgang Gindl-Altmutter from BOKU

Abstract:

Lightweight foams are of general interest in a diversity of applications because of their low density and high specific surface area. Since there is a special interest to replace fossil-based polymers with polymers from renewable and biodegradable resources, cellulose nanofibrils and lignocellulosic nanofibrils were used to prepare bio-based foams, which could e.g. be used for insulating materials.

For the preparation of the porous materials, lignin-free bleached wood pulp, termed MFC, and microfibrillated cellulose with 17 % lignin content (MFLC) were used in aqueous suspensions. Furfuryl alcohol and maleic anhydride were added to the slurry, resulting in ratios of fibrils to furfuryl alcohol of 0.00, 0.03, 0.06, 0.11, 0.20, 0.33, and 0.50. After mixing with a high-shear blender, the mixtures were placed in an oven at 80 °C for 24 h in order to polymerize the furfuryl alcohol. Thereafter, foams were prepared by freeze-drying.

Characterization of the foams was performed by Scanning Electron Microscopy (SEM), ATR-Fourier-Transform Infrared Spectroscopy (FTIR), Thermogravimetric Analysis (TGA), as well as mechanical testing (e.g. compression tests). Furfuryl alcohol content was found to significantly affect foam density. Furthermore, mechanical properties were significantly higher for MFLC-based foams.

Stefan Veigel

University of Natural Resources and Life Sciences, Austria

Title: Nanocellulose-modified Oil-based Wood Coatings

Time : TBA

Biography:

Abstract:

Due to their bio-based character, oil-based coatings are prevailing more and more in wood surface finishing. These coatings impart appealing optical and haptical properties to the wood surface but lack sufficient protection against water and mechanical influences. The aim of the present study is therefore to modify oil-based coating formulations by the addition of hydrophobised cellulose nanofibrils (CNF) which are thought to form an ultra-thin protective layer on the wood surface without affecting its pleasant optics and haptics. Hydrophobisation of CNF was performed by an esterification with different carboxylic acids as well as by a modification using the paper sizing agent alkyl ketene dimer. Modified nanofibrils were added to an oil-based coating material either by a solvent exchange approach or spray drying and subsequent addition of the dry cellulose powder. Oil formulations containing 1 wt% CNF modified with (2-Dodecen-1-yl) succinic anhydride showed almost no sedimentation after 48h. An enhanced abrasion resistance along with a slightly higher resistance to chemicals was found for oak wood surfaces coated with cellulose-modified oil formulations. The increased surface resistance might be attributed to the loose network structure of CNF which effectively prevents the oil from penetration into the wood surface, thus forming a protective CNF/oil composite layer on the wood surface.

Richard Vendamme

Flemish Institute for Technological research

Title: Development of Thermosetting Polymers from lignin Model Compounds and Depolymerized Lignins

Biography:

Richard Vendamme obtained an engineering degree and a master degree in chemistry in Lille (France) in 2001. He subsequently moved to the Max-Planck Institute for Polymer Research in Mainz (Germany), where he prepared his PhD working on stimuli-responsive liquid crystalline gels. In 2004 he was awarded a JSPS postdoctoral fellowship and started his career at the Institute of Physical and Chemical Research (RIKEN) in Tokyo, Japan. In 2007, he joined the European headquarter of Nitto Denko, one of Japan’s leading diversified materials manufacturers, where he was successively involved in R&D, innovation and techno-marketing. He is working at VITO since April 2017 in the field of bio-aromatics and bio-polymer development. Richard is author of 20 scientific publications, 11 patents, and also holds an executive MBA from Vlerick business school.

Abstract:

Lignin is the most abundant source of renewable ready-made aromatic chemicals for making sustainable polymers. However, the structural heterogeneity, high polydispersity, limited chemical functionality and solubility of most technical lignins makes them challenging to use in developing new bio-based polymers.

Recently, greater focus has been given to developing polymers from low molecular weight lignin-based building blocks such as lignin monomers or lignin-derived bio-oils that can be obtained by chemical depolymerisation of lignins. Lignin monomers or bio-oils have additional hydroxyl functionality, are more homogeneous and can lead to higher levels of lignin substitution for non-renewables in polymer formulations. These potential polymer feedstocks however present their own challenges in terms of production (i.e. yields and separation), pre-polymerization reactions and processability.

This talk provides an overview of recent developments on polymeric materials produced from lignin-based model compounds and depolymerised lignin bio-oils with a focus on thermosetting materials. Particular emphasis is given to epoxy resins, polyurethanes and phenol-formaldehyde resins as this is where the research shows the greatest overlap between these two types of feedstocks. The common goal of the research is the development of new economically-viable strategies for using lignin as a replacement for petroleum-derived chemicals in aromatic-based polymers.

Zayniddin K. Muhidinov

Institute of Academy of Sciences of the Tajikistan Republic

Title: Characterization of a polysaccharide from Eremurus hissaricus roots growing in Tajikistan

Biography:

Zayniddin K. Muhidinov obtained his University degree in Chemistry at the Tajik State University and a Ph.D. in Chemistry of Natural Compounds and Doctor of Science degree in Polymer Chemistry at Chemistry Institute of Academy of Sciences of the Tajikistan Republic. Dr. Muhidinov passed doctoral courses at the All India Institute of Medical Sciences, New Delhi, India in 1998-1999 and the Temple University, Philadelphia, PA USA in 2003. In last 14 years his group collaborating with USDA scientists in several projects pertaining to develop domestic agricultural byproducts into Drug Delivery Systems (DDS) for therapeutic purposes. His most recent project deals with the study of herbal biological active compounds. Professor Muhidinov is the author of a monograph; four chapters of the book (published by the American Chemical and Royal Societies) more than 290 scientific articles and abstracts, including 38 paper in peer reviewd journals, 10 patebts.

Abstract:

Statement of the Problem: Roots of medical plants are important resources of bioactive compounds including a polysaccharide, many of which, have been reported to possess various biological functions. Two types of water-soluble (WSP) and acid-soluble polysaccharides (ASP) with 23% and 8% yields, the molecular weight of 495 kDa and 179 kDa respectively were obtained from the roots of Eremurus hissaricus growing in Tajikistan in dormancy periods. The crude polysaccharides after deproteinization were purified by ion-exchange and gel filtration chromatography to obtain a homogeneous polysaccharide. The monosaccharide composition of WSP and ASP were analyzed by HPAEC-PAD. WSP was composed of D- mannose and D- glucose in 1.7:1 molar ratio. ASP content includes the pectic polysaccharide. IR spectra and analysis of 2D NMR analyses of WSP provide evidence that it has a backbone of (1→4)-linked ß-D-glucopyranosyl and ß-D-mannopyranosyl. The NMR and FTIR spectra of both crude and purified WSP has no differences. This fact probably indicates that WSP has no significant impurity. The carboxyl group of WSP is highly esterified. The NMR analyses of the ASP and deproteinated ASP polysaccharides suggest that the samples are composed of rhamnose, galactose or glucose, xylose, and arabinose, with partially methyl- and acetylated carboxyl groups, which may be consistent with a branched pectic rhamnogalacturonan. Unfortunately, monosaccharide analysis has not yet been performed on these samples. The NMR spectra of the ASP-S3 sample is similar to the other two, but it appears to lack resonances assignable to xylose. It is unclear what this means. The bands at 801 cm-1 in the FTIR of the ASP samples were characteristic of the a-pyranose configuration of sugar unit of the pectin polysaccharide, while the absorption in the region of 880-890 cm-1 confirms the presence of ß-pyranose configuration of another sugar residue in the WSP.

Fig. 1. Tuber roots of Eremurus Hissaricus (1&2) and schema for extraction (3), purification of WS- and AS- polysaccharides (4) and structural analysis (5).

- Smart and Functional Polymers

Location: 2

Session Introduction

Jack Y. Lu

University of Houston-Clear Lake, USA

Title: New Functional Polymers

Biography:

Abstract:

New Functional PolymersNew functional polymers represent one of the current area of research interests in materials science. It is well-known that functional materials may have wide range of applications, where they can be used as ion exchangers, molecular sieves and enhancing hydrogen storage capacity etc. However, energetic polymers have not been well explored in the field. A few newly assembled polymers with energetic functions and potential applications will be discussed along with the novel structural features.

- Biodegradable Polymeric Materials

Location: 1

Session Introduction

Ivan Chodak

Polymer Institute SAS, Slovakia

Title: Effect of biodegradation on physical properties of PLA-based blends

Time : 11:20-12:05

Biography:

IVAN CHODAK Affiliation : Polymer Institute of the Slovak Academy of Sciences Job status : Senior scientist Department of Composite Materials Full Professor of Macromolecular Science, Slovak Technical University Education and Professional carreer : 1960 - 1965 Slovak Technical University, Faculty of Chemical Technology, Bratislava 1965 - 1970 Matador, rubber factory, Bratislava 1970 - Polymer Institute, Slovak Acad. Aci., BRATISLAVA 1970 - 1973 PhD Student 1975 PhD 1973 - 1981 Scientist 1982 - 2010 Head of Department of Composite Thermoplastics 1989 – 1990 Deputy Director 1997 DSc 2000 Associated Professor of Macromolecular Science 2005-2009 Member of Presidium of the Slovak Academy of Sciences 2006 Full professor of Macromolecular Science LEAVES OF ABSENCE 1981 - 1982 One-year sabbatical leave at Clarkson University, Potsdam, NY 1983 - 1997 Several short-term stays (up to two months), e.g. Techn. Univ. Eindhoven, Univ. Quebec Trois Rivieres, ENSAM Paris, CNR Arco Felice, etc. AWARDS 1989 - Slovak National Prize for excellent results in polypropylene modification (member of a team of 5 scientists) 1993 - Silver Medal of Dionýz Štúr for "A Significant Contribution to a Development of Natural Sciences" 2003 – Medal of Slovak Academy of Sciences for Achievements in Science 2012 – Award of the Minister of Education of Slovak Republic as the Scientific Personality of the Year 2014 – Gold Medal of the Slovak Academy of Sciences Scientific interests Multiphase systems with a modified polymeric matrix, synthesis and properties.

Abstract:

Biodegradable plastics undergo to substantial changes due to degradation by enzymes produced by various bacteria. From application point of view, modification of physical properties is important, occuring even when the testing specimens are apparently unchanged.

Degradation in compost of polylactic acid (PLA), PLA with a plasticizer triacetin (TAC), and a mixture of PLA / polyhydroxybutyrate (PHB) / TAC proceeded at temperature 58 oC up to 16 days and the biodegradation degree was determined by measuring the content of evolved carbon. The degradation rate was found to vary a little for the three samples.

While the biodegradation tests were performed almost to complete biodegradation of the materials to carbon dioxide and water, physical properties could be measured only for the first 8 days and in some cases up to 16 days when it was possible to separate the material from the compost. At longer periods the materials have been disintegrated to small fragments and separation of the sample from compost was impossible.

Number of testing methods was applied. Molecular weight and molecular weight distribution was determined by GPC, supported by measuring the viscosity by rheology. Structure of the materials were estimated from changes in Tg and crystallinity. Mechanical properties of samples and the data were compared with information obtained from dynamic mechanical analysis (DMTA).

The conclusions have been made regarding the effect of TAC and PHB presence on the biodegradation of PLA, and related changes concerning the structure / mechanical relations.

Acknowledgement: The supported from projects VEGA 1/0570/17, APVV 15-0741 is appreciated.

Péricles Lopes Sant’Ana

State University of Sao Paulo, Brazil

Title: Plasma surface treatment of recycled polymers for food packaging

Time : 12:50-13:35

Biography:

The change of habit and the increase in consumerism in the last decades have led to technological innovations and consequently to the greater production of consumer products, which has generated an increase in the production of packaging. However, its disorderly disposal generates a large volume of solid waste, which is associated with the environmental impact. Concern for this situation, we ought to develop alternative means to reduce such impacts and may highlight the reuse and recycling of packaging. Plastics represent the largest share in the value of Brazilian packaging production, corresponding to 38.85% of the total. The employment level of the packaging industry reached 216973 jobs in June 2017. The plastic industry is the one that most employs, totaling in June 2017, 115307 formal jobs, corresponding to 53.14% of the total jobs in the sector. The plastics sector accounts for 59.58% of total imports. With respect to the results obtained in the last 10 years of research, the reuse of recycled commercial polymers by plasma surface treatment is emphasized. Then, it is possible to change the character of wetting of the polymers, being able to obtain high hydrophobic or high hydrophilic surfaces, maintaining very smoothness, high optical transparency in the visible region (up to 80%) and improving gas barrier (down to 1 g/m2day) mainly for PET and LDPE, which makes the plasma immersion treatment interesting for the food packaging

Abstract:

Pericles Lopes Sant’Ana has obtained his Bachelor’s Degree in Production Engineering from Federal University of Viçosa, Brazil. He has completed his Master’s and Doctoral Degrees in Materials Science and Technology from the State University of Sao Paulo. He has 10 years of experience in Research and Development, working with plasma surface treatment and thin films deposition for food packaging and optical devices. Recently he developed PVC, PET and LDPE polymers using plasma immersion techniques.